KLASSEN Armoured VIP Project MSE_1730

Armored Mercedes-Benz Sprinter 519 VIP Panel Van

Project Concept

The project is implemented as a complete conversion of a Mercedes-Benz Sprinter 519 Panel Van with left-hand drive, 2.0-liter diesel engine and 9-speed automatic transmission. The base vehicle is provided by the client. Subsequently, a comprehensive scope of work is carried out, including armoring, integration of special systems as well as the construction of a VIP zone in accordance with the technical specification.

The conversion is realized as a unified production- and engineering-related process: protection, load-bearing assemblies, door groups, glazing, cable routes, interior elements, multimedia systems as well as climate components are coordinated with one another in their geometry, weight and service accessibility. The result is a protected vehicle with a full-fledged VIP zone in which functionality and layout are executed taking into account the armored body structure.

Protection Level and Standards

The armoring is executed in accordance with EN 1522 / EN 1523 as well as according to the standard for bullet-resistant glazing CEN 1063 in classes B4 / B6.

The protection level is applied to the entire protected zone. The solutions for steel and glass are selected in such a way that they comply with the stated classes and at the same time ensure compatibility with the body and door structure after the increase in weight.

Armoring Materials and Protection Architecture (Steel / Glass)

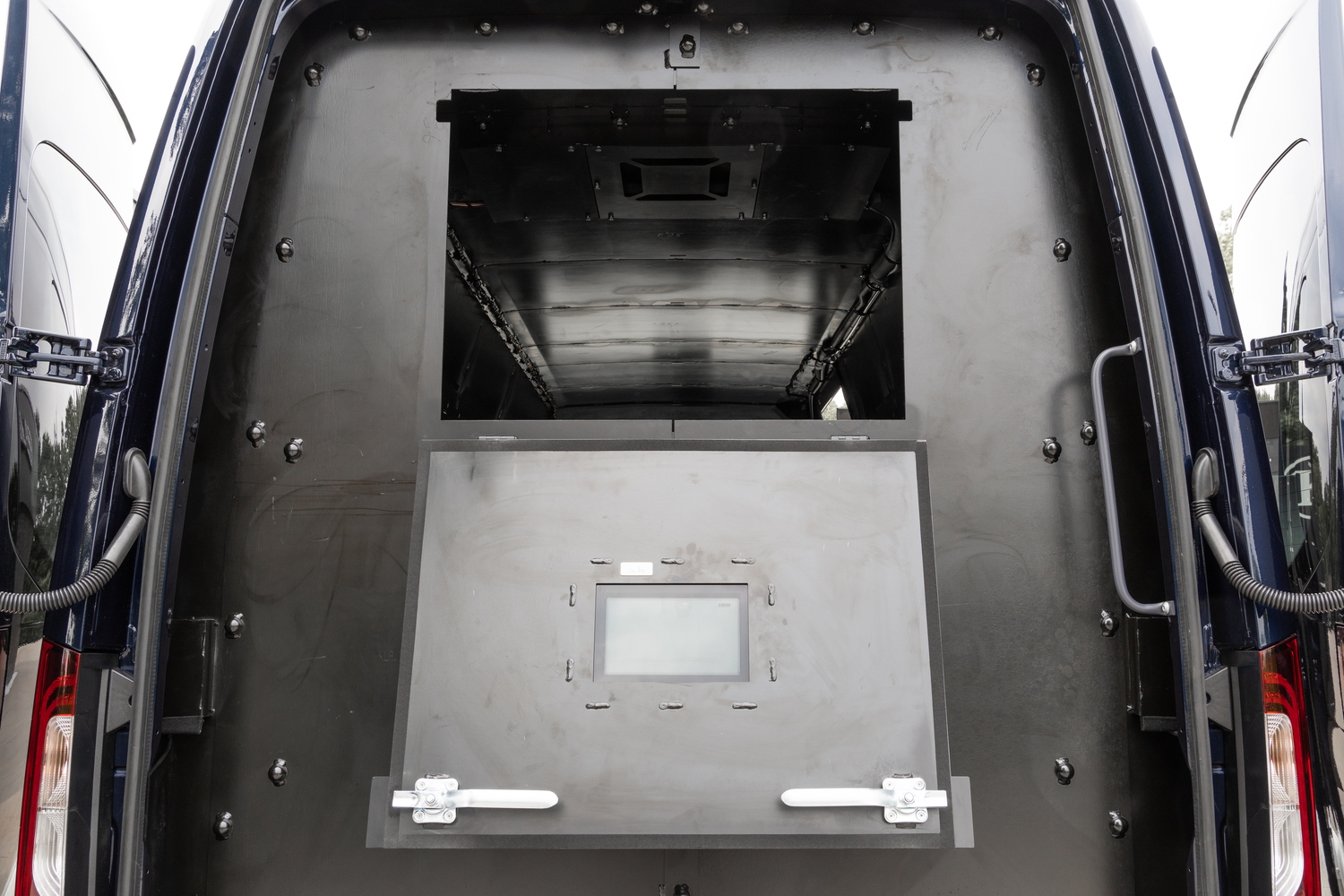

Protected Volume and Armor Coverage

The protection is executed as a fully protected cargo or VIP area with coverage of the relevant surfaces. The side surfaces, the front surface toward the driver’s cabin, the rear section, the vehicle floor as well as the roof are armored. This creates a continuous protected contour within the VIP zone without open “unprotected” surfaces within the defined volume.

The floor is executed using 2 mm VA steel in accordance with the specification.

The roof additionally takes into account a shooting scenario at an angle, as the project provides for roof protection taking into consideration an angle of 45° (the geometry of the roof protection as well as the overlap zones are designed under this angle).

Corrosion Protection of the Armored Steel Components

The armored steel is cathodically dip-coated (Industrial Coating). This technological process ensures uniform protection of the metal against corrosion, including hard-to-reach surfaces and edges, which is of particular importance for armored elements installed within body cavities.

Construction of Door Areas, Pillars and Load Transfer

After armoring, the doors exhibit a significantly increased mass. The project provides specially developed door hinges executed as CNC-milled units and attached directly to the armored steel structure, not to the standard body shell.

Additionally, it is specified that the body pillars are structurally adapted: they fulfill a dual function – they ensure ballistic protection in the pillar area and at the same time absorb the load of the reinforced hinges and the armored doors and transfer it further. Such adaptation of the pillars is required in order to ensure long-term use of the armored doors without distortion, sagging or premature wear of the assemblies.

Ballistic Glazing (Arrangement)

In the protected area additional elements of ballistic glazing are integrated, namely:

two ballistic panes – one each in the left and right side wall of the cargo or VIP area;

one ballistic pane – in one of the rear wing doors.

These elements fulfill the function of controlled visual communication or viewing capability and are integrated into the overall protection concept within protection class B4/B6.

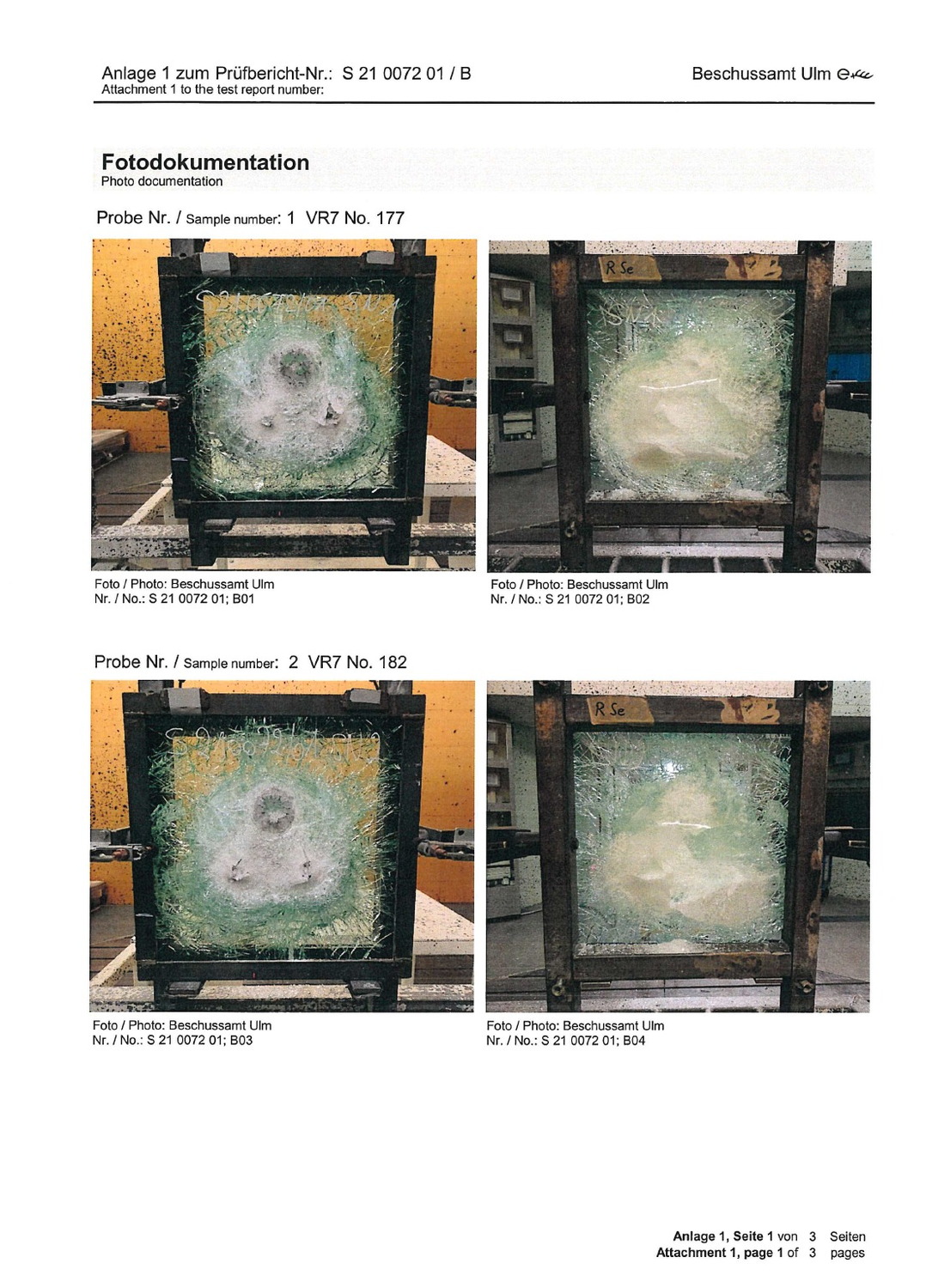

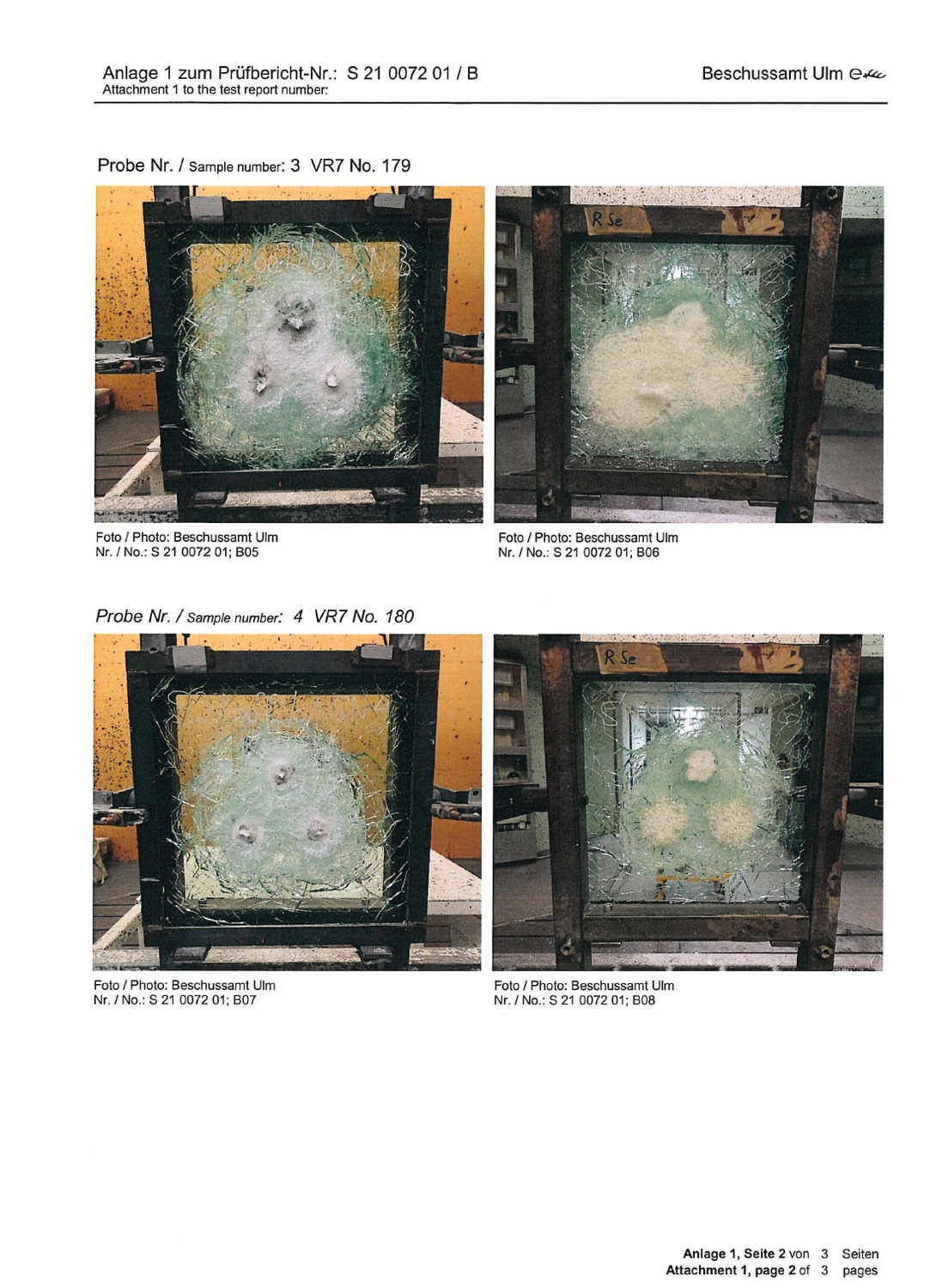

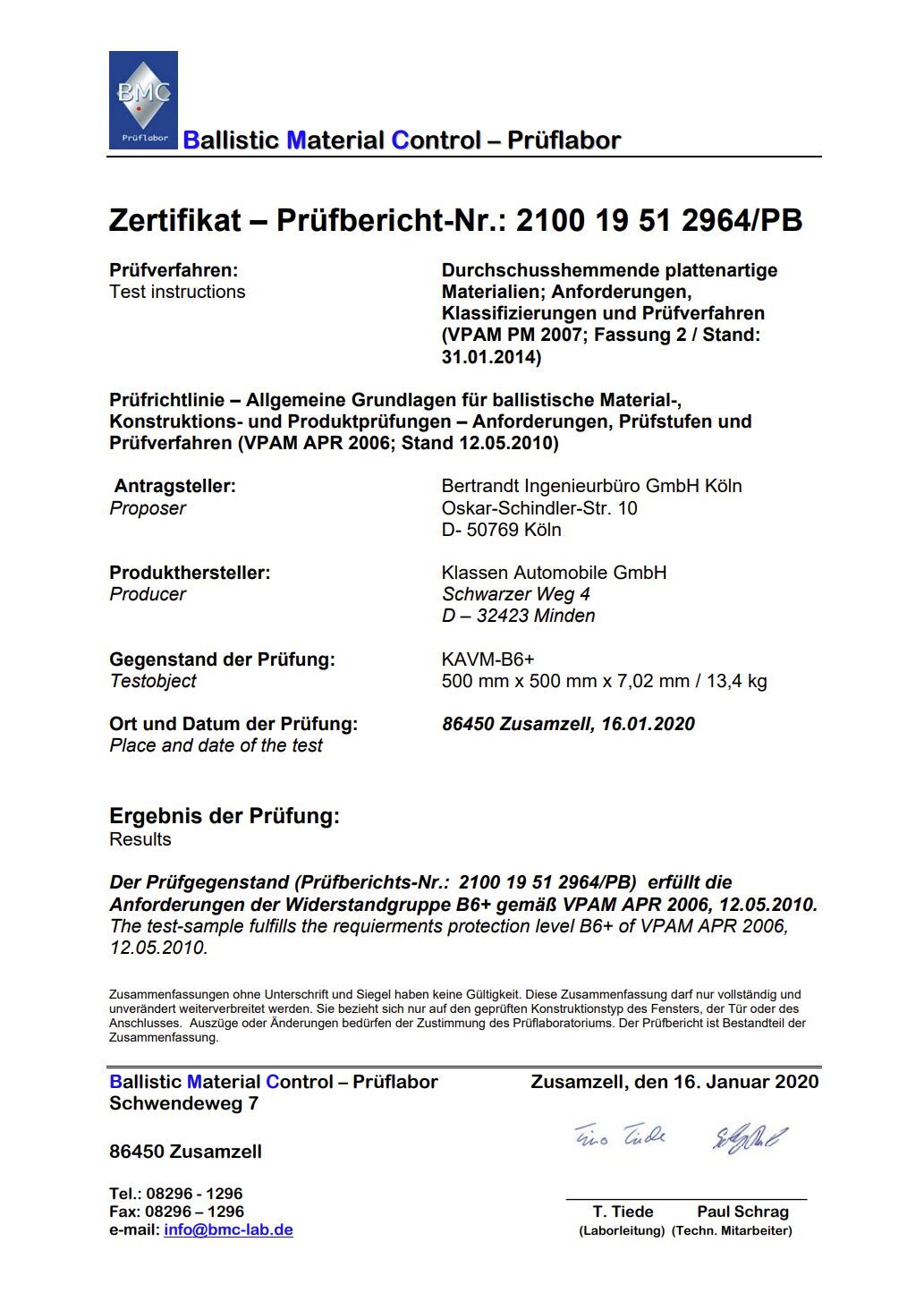

Certification and Firing Tests (Glass / Steel)

The project provides the availability of conformity certificates for ballistic glass and armored steel with confirmation through firing tests, including the execution of real firing tests on samples. For the production description this is recorded as part of the project documentation: certificates for materials as well as results of ballistic tests are provided in the vehicle documentation package.

It is expressly emphasized that the certification documents refer specifically to the components used (glass/steel) and not merely to a declared protection class.

Technical Solutions (Assemblies, Systems, Integration)

Hinges, Mountings and Service Accessibility of the Doors

Specially developed hinges are used, which are attached directly to the armored steel structure. From a production perspective this means: in the area of the hinges a load-bearing base is formed on the armored contour frame; the assembly is designed for the increased door weight after armoring; at the same time the possibility of adjustment as well as service accessibility is maintained without having to dismantle major interior elements.

Structurally Adapted Pillars

The pillars are executed as part of the armored system and at the same time are structurally designed as load-bearing elements for absorbing the door loads. This ensures the stability of the door opening geometry as well as uniform functioning of locks and seals over a long service life.

Pre-installation for Communication and Signal Systems

The installation of a roof antenna with prepared VHF wiring is provided. From a production perspective this means: cable routes are laid before completion of the trim work; connections are routed out at defined points; thus clean integration without subsequent visible add-on structures in the interior is ensured.

Communication and Warning Systems

The intercom system is executed in combination with a Public Address function (standard version). This enables controlled communication between the VIP area and the driver compartment as well as a public announcement function when required.

An alarm siren is installed in the engine compartment in accordance with the principle of protected positioning – the component is located in an area with restricted external access and does not occupy usable volume in the VIP area.

Passive Safety for All Passengers

3-point seat belts are provided for all passenger seats. From a production perspective this includes reinforcement of the mounting points as well as coordination of the belt routing with the seat configuration and the respective fastening systems.

Exterior

The exterior is executed as a complete package of external elements in AMG style. A front spoiler, a radiator grille design in the corresponding style, side skirts as well as a rear spoiler as a unified design solution are provided. From a production perspective this includes adaptation of the components to the body, correct gap dimensions, compatibility with standard mounting points as well as coordination with armored zones (in particular in the area of cable passages and service access points).

The installation of a ski box on the roof as well as chrome wheel covers is provided.

In order to improve entry and exit comfort, an electric side step is integrated. It is geometrically coordinated with the sill area, side skirts and the on-board electrical system.

Interior / VIP Area

VIP Seats and Seat Mounting

Electric luxury seats are used in the VIP area. The electric adjustment enables precise adaptation of the seat position to the passenger’s body dimensions as well as adjustment to various usage scenarios such as working or relaxing.

Seat heating is executed as uniform heating of the contact surfaces of seat and backrest, which is particularly relevant for winter use and long journeys.

Seat ventilation ensures the removal of heat and moisture from the contact zones and increases comfort in summer conditions as well as during intensive use.

The massage function is integrated into the backrest structure and serves to reduce signs of fatigue during longer journeys.

Each seat is equipped with an integrated 3-point seat belt that is tested in accordance with applicable regulations and TÜV standards. From a production perspective this means correct positioning of the upper deflection point, coordination with the seat geometry as well as reinforced mounting points on the structure and floor.

For the installation of the luxury seats an individual mounting construction is manufactured. This includes the development and production of load-bearing elements that ensure the correct seat height, seat angle as well as load distribution onto the floor structure, taking into account the armored structure beneath the floor and trim.

For the seats of the third and fourth row a manual individual adjustment is provided, enabling simple and reliable adjustments without additional complexity of electrical components in the rear area.

For seats 5 and 6 the equipment with ISOFIX fastening systems is provided. The ISOFIX mountings are structurally integrated into the seat structure and executed in accordance with applicable safety requirements for the attachment of child seats. The positioning of these two seats as well as the integration of the ISOFIX systems correspond to the configuration shown in the attached photo documentation.

Leather Processing of the Seats and Armrests

Leather upholstery of the luxury seats as well as of the armrests is carried out. From a production perspective this includes material selection, cutting, covering, seam execution as well as color and structural coordination with the remaining interior zones. The leather is used as a functional surface; therefore wear resistance, clean transitions and a long-term stable appearance are essential.

KLASSEN Interior Step

A KLASSEN step is provided, which improves ergonomics when entering and exiting. The adjustment is carried out manually and individually so that it can be adapted to the specific interior configuration as well as to the floor height after insulation and covering.

Electrically Extendable Drawers Under the Seats

Electrically extendable drawers are integrated under the front VIP seats. These serve for structured and concealed storage of documents, personal items and accessories. From a production perspective this includes guide rails, electric drive, locking in the closed position as well as coordination with cable routes and service access under the seat.

Central Armrest Between the Main Seats

Between the main seats a central armrest module is installed, which fulfills both a comfort and a storage function.

A refrigerator is integrated into this module. From a production perspective this means correct integration of ventilation or heat dissipation as well as stable power supply with protection within the on-board electrical system.

Cup holders are provided, which are integrated into the upper surface of the module and are executed in such a way that containers remain stably positioned during driving.

Additionally, a storage compartment for smaller items is integrated as well as a clock as a permanently visible information element in the interior.

Partition Wall and Entrance Area

The VIP area is separated from the driver compartment by a front TV partition wall. This construction serves the organization of privacy, acoustic separation of the zones as well as visual shielding of the passengers from the driver’s working area.

The partition wall receives a trim that is executed in accordance with the materials used and the styling of the interior. From a production perspective this means the manufacture of a load-bearing frame, installation of decorative panels as well as coordination of transitions and service access for cables, TV mountings and intercom components.

In the entrance area a functional element with an arm support is provided, which additionally integrates a holder for an umbrella. This module serves the orderly organization of the space in the door area and prevents uncontrolled movement of items in the interior.

Roof Construction, Pillar Trim and Lighting

An individual roof construction is manufactured, which covers technical channels and forms a structural basis for lighting, ventilation elements and decorative components.

The roof construction as well as the pillars are fully trimmed. This creates a uniform interior geometry with clean transitions and concealed structural elements of the body and the armored structure.

The KLASSEN “Starlight Headliner” system is integrated. From a production perspective this means the installation of light elements in the roof with uniform distribution, correct electrical supply as well as service access to control units.

Additionally, RGB ambient lighting is integrated, executed as controllable lighting zones and coordinated with the interior control system.

Floor Structure and Floor Coverings

A floor construction is executed that is tested in accordance with the applicable legal norms and EU standards. From a production perspective this includes the manufacture of a load-bearing base, coordination with seat mounting points, cable passages as well as armored components.

Subsequently, insulation is installed, consisting of high-quality sound and thermal insulation. This is executed in layers with overlap in order to reduce driving noise and aggregate noise as well as to ensure a stable temperature in the VIP area.

In the basic version a carpet floor covering with integrated wooden elements is used. Additionally, a further floor covering for the VIP area is provided, which completes the overall visual appearance and increases wear resistance in heavily frequented zones.

Side Trim Panels, Wood Elements, Tables, Curtains, Lighting and Connections

Individual side trim panels for the VIP area are manufactured, adapted to the specific geometry of the body and the armored structure. This is not a simple covering, but a complete interior element with integrated functions.

The side trim panels are fully trimmed, including coordination of materials, transitions, decorative inserts as well as service access points.

Elements made of fine wood are used in the VIP area. From a production perspective this includes the manufacture of individual components, their fitting, surface treatment as well as coordination of color and structural effect between different interior zones.

Electrically extendable tables are integrated for the designated seats. The construction takes into account structural stability, safe gap dimensions as well as reliable locking in the retracted position. The electric drive is coordinated with the interior control system.

Decorative pillar elements with integrated lighting are installed. These fulfill both a design function and the covering of technical transitions between panels.

The opening mechanism of the sliding door is integrated into the side trim panel. As a result, the interior design remains free of visible additional control elements.

Electric curtains are installed for the side windows. Drives and guide rails are integrated into the trim without impairing the interior geometry.

RGB ambient lighting is integrated as part of the interior lighting system and is controllable.

USB ports are provided in the interior. Additionally, the following types of connections are integrated: 220V socket, USB port for data transmission, USB port for charging function, main switch in the VIP area as well as HDMI connection. From a production perspective this includes the routing of power and signal lines, the installation of voltage converters as well as accessible positioning of the connections for the passengers.

Multimedia and Comfort Systems

In the VIP area a 43-inch LED television is installed as the main display. This is mounted in the front area of the VIP zone within the TV solution, ensuring rigid mounting, absence of vibrations as well as service access to the wiring.

Additionally, a 22-inch LED television is integrated as a second screen. This allows alternative usage scenarios, for example parallel display of different content or division of media usage between passengers.

A DVB-T2 antenna for receiving digital television signals is provided. It is expressly taken into account that a functional test in the country of destination is required, as broadcasting formats and network coverage vary depending on the country.

For supplying alternating current consumers, a voltage converter from 12V to 220V is integrated. This component is part of the energy system of the VIP zone and is dimensioned in terms of performance and safely integrated into the on-board electrical system. Protective measures, line protection and service access are taken into account.

The audio system is executed as an overall system. Two-way speakers are installed in the passenger area, covering the mid-range and high-frequency range. Additionally, a subwoofer is integrated for the low-frequency range. The positioning is carried out in such a way that uniform sound distribution in the interior is achieved without generating resonances with trim panels or armored components.

Apple TV is integrated as a media source and enables modern usage scenarios such as streaming, access to media libraries or transmission of content from external devices. Integration is carried out via HDMI as well as stable power supply.

An intercom system is installed, which enables communication between the VIP area and the driver compartment without having to open the partition wall and without impairing privacy.

In the VIP area the KLASSEN Remote System is installed. This enables centralized control of interior functions such as lighting, climate control and multimedia via an iPad. For this purpose, an iPad Mini is integrated, which is fixed in a docking station. The docking station simultaneously serves for secure fixation as well as the charging function of the device.

For monitoring the surroundings, a front camera as well as a rear-view camera are integrated. The Quattro Split Screen System enables the simultaneous display of multiple image sources on the screen. This is particularly relevant when maneuvering, in confined spaces or for monitoring the surrounding area.

The air conditioning system of the VIP zone is executed as a separate system with cooling and heating function. A dedicated control unit in the VIP area enables independent regulation by the passengers. An individual construction of air ducts is carried out, including the integration of air outlets in the roof and side areas. Additionally, an autonomous auxiliary heater from Webasto is installed, which enables heating independently of engine operation and increases efficiency in winter operation.

Additional Systems and Options

Driver Area – Trim and Coordination with the Project

The driver and front passenger seats are reupholstered or trimmed in accordance with the project execution, coordinated with the materials and quality level of the VIP zone. Likewise, the driver and front passenger doors are trimmed so that the front vehicle area corresponds to the overall standard of the conversion.

The steering wheel receives a leather covering. This improves haptics, increases wear resistance and ensures stable grip control.

The dashboard can be equipped with elements made of fine wood as well as with a Soft-Touch surface. From a production perspective this includes surface preparation, application or installation of the materials, control of transitions as well as avoidance of noise formation after installation.

A carpet floor covering is provided for the driver area, which visually completes the interior and contributes to acoustic improvement.

Sanitary Module (WC)

The possibility is provided to equip the vehicle with a sanitary module. The module includes a partition wall with door, whereby a separate enclosed area is created.

The module includes a toilet, a waste container, a washbasin, a fitting, a mirror, a lower cabinet under the washbasin as well as a hygiene shower. Additionally, lighting and ventilation are integrated.

From a production perspective this includes routing of water supply and wastewater systems or corresponding modular solutions, electrical supply, ventilation ducts or outlets as well as service access.

Basic Options and Consumables

In the VIP area a Soft-Touch surface is applied to selected elements. This serves to reduce reflections, improve haptics as well as visually unify the surfaces.

Consumables are taken into account as part of the production process. These include adhesives, fastening elements, insulation materials, electrical components as well as surface materials that are required for correct installation and warranty-quality execution.

Additional Interior Options

Additional armrests are provided for the rear seats, which improve ergonomics and complete the overall appearance of the seating system.

Seats five and six can be installed on a podium. This design feature serves to adapt the seat geometry, improve the sight line or integrate additional systems beneath the podium.

A wireless charger for mobile devices can be integrated. This is installed in an area that is easily accessible for the passengers.

Additional cup holders can be provided and are integrated in coordination with the central and side modules.

Special Options from the Armoring Package

As part of the special options of the conversion the following are provided: cathodic dip coating of the armored steel components, the roof antenna with VHF preparation, the intercom system in combination with Public Address (standard version), the alarm siren in the engine compartment, front and rear rubber floor mats as well as 3-point seat belts for all passenger seats. These positions are part of the production-technical execution of the armored vehicle.